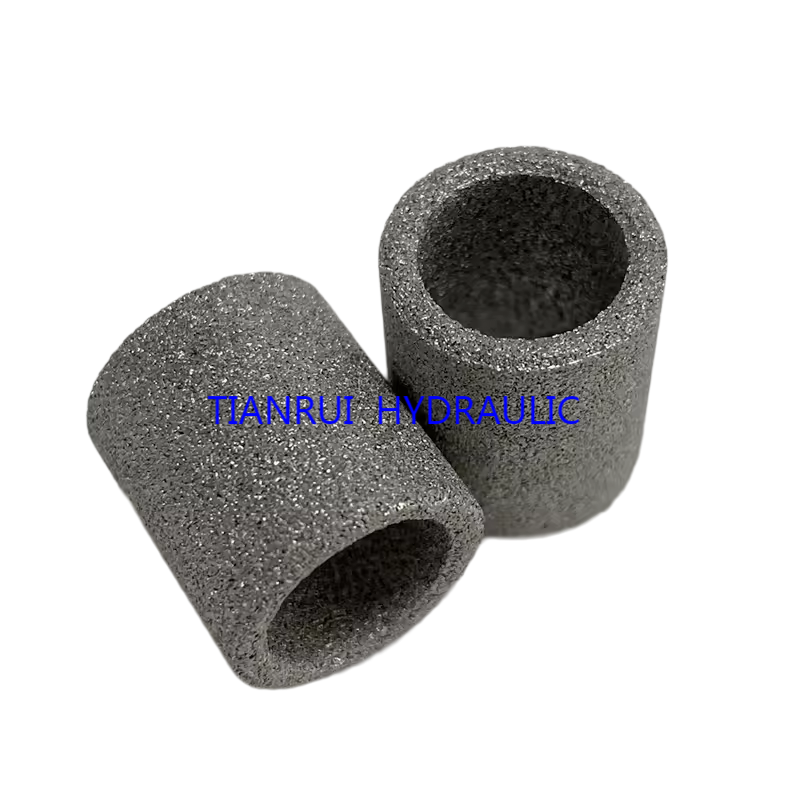

Product Description

| Item Name | Porous powder sintered stainless steel filter element | |

| Filtration precision | 0.1um - 80um | |

| Shape | Tubular, Plate, Bar, Disc, Cup, Plate, ect | |

| Specification(mm) | Thickness | 0.5-20 |

| Width | Less than 250 | |

| Work environment | Nitric acid, sulfuric acid, acetic acid, oxalic acid, phosphoric acid, 5% hydrochloric acid, molten sodium, hydrogen, nitrogen, hydrogen sulfide, acetylene, water vapor, hydrogen, gas, carbon dioxide gas environment. |

|

Advantage

1. Uniform structure, narrow pore size distribution, high separation efficiency.

2. High porosity, filtration resistance, high penetration efficiency.

3. High temperature, generally below normal 280 degrees.

4. Good chemical stability, acid corrosion, has antioxidant properties.

5. No particle shedding, not to dope the formation of secondary pollution, comply with food hygiene and pharmaceutical GMP requirements.

Applications

1. Pharmaceutical Industry

Active pharmaceutical ingredients, such as solvent solution, decarburization filtration of material filtering.Pharmaceutical industry infusion, injection, oral liquid concentration with link of the decarburization filtration and security filtration for the dilute with terminal filter.

2. Chemical Industry

The liquid of chemical industry products and raw materials, and the decarburization filtration of material and precision filtration of pharmaceutical intermediates. Superfine crystal,the filter recycling of the catalyst, the precision filtration and heat conduction oil system after absorption of resin.Removing the impurities in the materials, and the catalytic gas purification, etc.

3. Electronic Industry

Electronic, Microelectronics, semiconductor industrial water filter, etc.

4. Water Treatment Industry

It can used in the security filter SS housing as the pre-treatment for UF, RO, EDI system, the filtration after the ozone sterilization and the ozone after aeration.

5. Sewage Treatment

The micropore pure titanium aerator compared with the normal aerator, the energy consumption of the micropore pure titanium aerator is lower 40% than the normal aerator, the sewage treatment is nearly doubled.

6. Food Industry

The beverage, wine, beer, vegetable oil, soy sauce, vinegar clarification filtration.

7. Oil Refining Industry

The oiled field water filter,and the security filter SS housing before the reverse osmosis in desalination field

Filter Pictures